选择语言

选择语言

Influence of low voltage withdrawable switchgear structure design on electrical performance

Low-voltage complete switchgear completes the redistribution of electric energy in the low-voltage power distribution system, and realizes the control, measurement, protection, conversion and other functions of the power grid. All places that use electric energy need to be equipped with low-voltage complete equipment. It plays a pivotal role in the national economic construction, especially in various industries such as petroleum, chemical industry, metallurgy, construction, and mining. Therefore, the quality level of low-voltage complete switchgear, especially the stability, reliability and safe operation of electrical performance are closely related to the national economic strength, scientific and technological development and people's living standards. In the late 1980s, with the transformation, expansion and construction of urban and rural areas, the electrical equipment market has expanded year by year, the number of manufacturers has increased, and the large investment in national power energy has also stimulated the development of the industry. Driven by this general trend, the varieties of low-voltage complete switchgear have been continuously refurbished, the quality has been continuously improved, and the electrical safety has been continuously improved.

1. Comparison of functional unit structures of several mainstream drawer switch cabinets

Low-voltage withdrawable switch cabinets have no knife switches, which reduces the installation space of components and increases the number of circuits in the cabinet. At the same time, drawers of the same specifications can be interchanged. When a line fails, the spare drawer can be replaced in time to reduce the power outage time. Therefore, it is widely used in low-voltage complete sets of equipment. Whether it is output, variety, or electrical performance, it exceeds that of fixed cabinets. At present, there are three types of domestic mainstream drawer cabinets in market demand, namely MNS, GCS, and GCK (GCL). These three cabinet types are basically similar in appearance, but there are differences in their internal functional unit structures. When choosing a cabinet type, customers should choose according to its characteristics and actual needs. The following is a comparison of the three cabinet types in the form of a simple table based on the products that have obtained 3C certification from Chint Complete Set Company.

2. The influence of overall structure on electrical performance

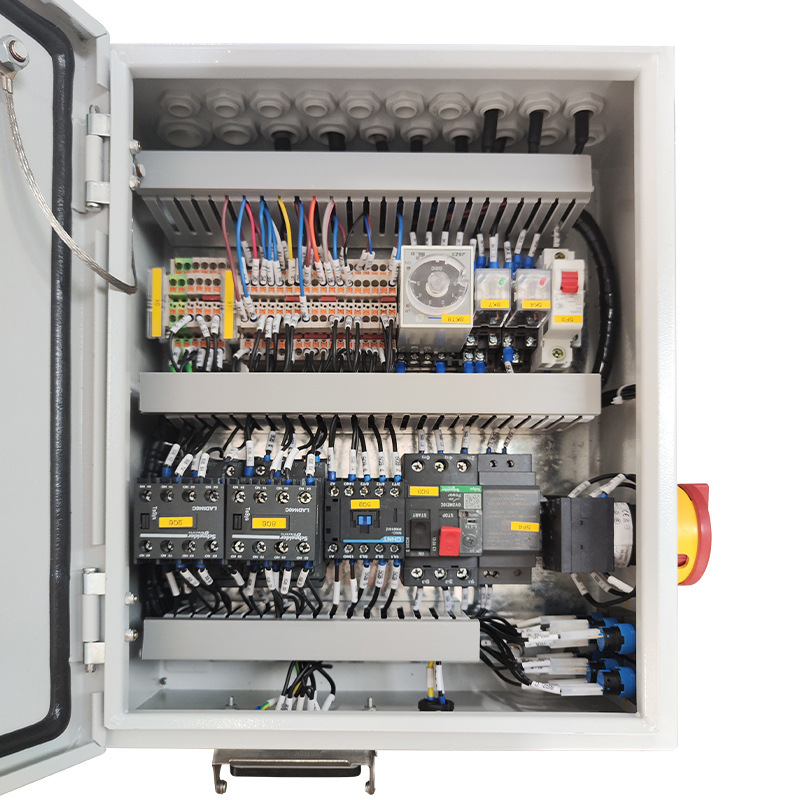

The overall structural layout of the low-voltage drawer cabinet should be beautiful, generous, and smooth in lines. The division of the drawer functional units should be reasonable and meet the requirements of electrical parameters.

The frame structure of the "C" profile is simple and easy to install. At present, low-voltage drawer switch cabinets have been widely used.

Whether the overall structural design of low-voltage switchgear is reasonable involves four aspects of electrical performance requirements:

1. Insulation coordination

2. Anti-dynamic thermal stability

3. Improving the protection capability of fault arc

4. Temperature rise

① Strengthening the insulation performance of the equipment will help improve the overall overvoltage resistance.

The insulation coordination of the drawer switchgear is determined by the use environment conditions of the equipment, the location of the power supply system (overvoltage category), the performance of the insulation material and other factors to determine the minimum electrical clearance and creepage distance. The group of insulation materials is divided into 4 categories according to the numerical range of the material's tracking index (CTI), and the material combination is Ⅰ600≤CTI; Ⅱ400≤CTI<600; Ⅲ175≤CTI<400E; Ⅳ100≤CTI<175E. There are many insulating parts in the low-voltage drawer cabinet, such as insulators, busbar clamps, functional boards made of polycarbonate engineering plastics, secondary connectors, etc., which all affect the overall insulation performance of the cabinet. Statistics show that about 50% of accidents in my country's electrical products are caused by the insulation system. Of course, if the system is operating normally, as long as the insulation parts are selected appropriately and the quality meets the requirements, their electrical performance can still meet the requirements. After all, the voltage level is not high. If the pollution level is 4, the selection of insulation parts should be considered as a key point, such as the main busbar insulation in the cabinet adopts creepage distance and electrical clearance higher than the standard performance, and uses insulation parts with high CTI values.

② The dynamic thermal stability of the cabinet has always been the first consideration for customers. Especially in the case of high current, the structural strength of the cabinet is very high. Once a short circuit occurs, the cabinet should have the ability to withstand the short-circuit current. As a designer of the low-voltage cabinet, the first thing to consider is the fixing method and position of the horizontal main busbar. For example: the low-voltage incoming current of a large power plant with a 300MW unit is generally greater than 4000A. According to the process requirements, the main busbar is 3X3 (100X10), but in practice it will not be selected in this way. Generally, single-phase is arranged in two layers, with 2 80X10 rows on each layer, and fixed with a special insulating busbar clamp. Such a structural design disperses the impact of short-circuit current on the cabinet and greatly improves the overall short-circuit current resistance of the cabinet. Strengthening the contact pressure of the bolt connection part, ensuring the torque and angle of the bolt connection, can also resist the impact of short-circuit current.

③ In order to improve the fault arc protection capability of the equipment, metal partition isolation precautions are generally adopted inside the structure, insulation isolation of the live conductor, additional pressure relief channels, arc detection devices, etc.

There are many factors that cause fault arcs, which will not be discussed here. IEC4397-1 specifically stipulates the purpose of arc protection, and the final requirements are: ① prevent touching the dangerous parts of adjacent functional units; ② prevent solid foreign objects from entering adjacent units from one unit of the complete set of equipment; ③ provide the highest possible level of personal protection. For this reason, the functional rooms of the cabinet are strictly separated, mainly divided into three parts: functional unit room, busbar room (horizontal busbar room and vertical busbar room), and cable room, which not only prevents the spread of accidents, but also facilitates live maintenance. This is the unique feature of the low-voltage drawer cabinet structure design. The purpose is to limit the generation of arcs, limit the intensity and duration of arcs.

In order to prevent the fault arc generated in the switchgear from causing harm to nearby personnel, a pressure relief device is added to the top of the cabinet. When the fault arc is ignited, the pressure generated forces the pressure relief device to open, and the hot gas is discharged to the top of the cabinet, thereby ensuring the safety of personnel. This passive arc protection function is a measure that has to be taken when an arc has occurred. It is mainly to protect personal safety, but it is an indispensable and important link in the cabinet structure design. By the way, it is particularly important to develop low-voltage complete switchgear with fault arc protection and verify it according to IEC-1641 <<Fault Arc Test Guidelines for Enclosed Low-Voltage Complete Switchgear and Control Equipment>>.

④The temperature rise of the drawer switchgear is also an important indicator for examining the cabinet structure design. The temperature rise in the cabinet is related to the size of the shell, the installation form of the shell, whether it has ventilation slots and the size of the ventilation slots, the number of internal horizontal partitions, the effective loss of components and the number of drawer units. As a manufacturer, the design institute cannot change the various parameters of the drawings after completing the product design. In the actual design process, some parties or design institutes have equipped too many drawers in order to save space and the number of equipment. Although the installation can be completed, the temperature rise of the cabinet is ignored, especially in summer. If the distribution room is not well ventilated, the temperature rise in the cabinet is often too high during use, which causes equipment damage, insulation damage, and short circuit accidents. This should attract the attention of our designers and it is necessary to raise it to the other party.